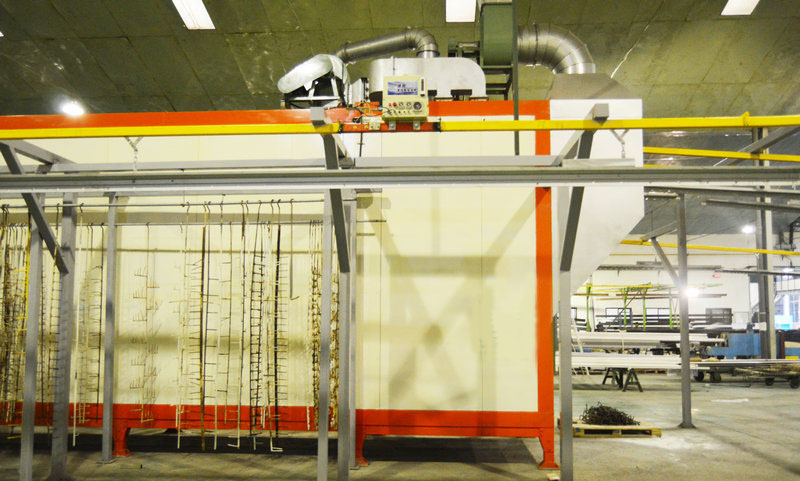

Drying oven is to dry the chromium film after chromium, so that there is no residual water on the surface. After the workpiece is cleaned by the pretreatment equipment, it will enter the drying oven to remove the moisture on the surface of the workpiece, so as to facilitate the subsequent coating operation. If there is water left on the surface of the workpiece to enter the powder spraying process, the coating will produce bubble defects.

The drying temperature should not be too high, otherwise the converted film will lose too much crystal water and transform, resulting in the film loose and the adhesion of the coating decreased.

The heating of the drying furnace can be based on the needs of different customers using gas combustion engine or diesel combustion engine. The target temperature can be set by temperature control system. The furnace body adopts stainless steel structure.

After spraying, the powder of the workpiece needs to be baked in the oven to 200 degrees to solidify the powder.

The oven designed and manufactured by xintianyu has the following advantages through rigorous design:

1. Save energy through innovative design

2. Average temperature in the furnace to ensure drying and curing quality

3. Reduce baking time as much as possible to save space

4. It is easy to operate and can be used without long-term training

5. Hot air with infrared lamp for better baking efficiency